SAFETY IN A DOUBLE PACK IN BERLIN-FROHNAU. DEEPER LINEAR SHORING SECURES CONSTRUCTION PIT 10 METERS DEEP

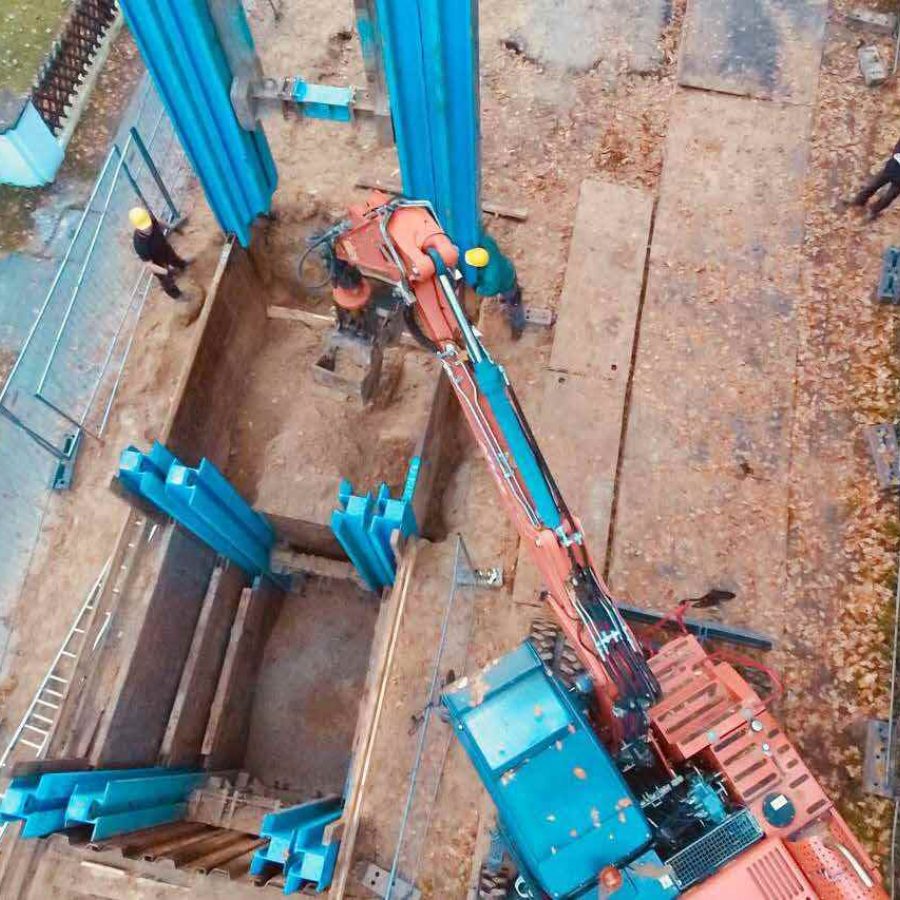

It was a construction pit safety measure of record-breaking dimensions - all construction partners involved in the sewer rehabilitation project in Berlin-Frohnau agreed on this. Carl Zauber Tiefbau GmbH had initially been commissioned by the Reinickendorf Civil Engineering Office to secure a so-called backfill site in the Waldsiedlung, which is characterized by individual buildings and villas. The subsequent camera inspection of the wastewater sewer and the resulting damage findings led to a follow-up order from Berliner Wasserbetriebe for the rehabilitation of the affected sewer section.After examining various alternatives, the contractor used the e+s linear shoring system from thyssenkrupp Infrastructure to secure the construction work on the pipeline, which was up to 10 meters deep. Particularly worthy of mention here is the fact that two linear shoring units were coupled together to secure the excavation pit, complementing each other in their mode of action after installation. And this was done while ensuring the load transfer required for the enormous depths achievable with this method.

The damage was preceded by a rain event of the century, which had caused a two-day state of emergency in large parts of Berlin at the end of June 2017 with flooded cellars, flooded streets and waterfalls in subway stations. Causes like these ultimately also caused the paved road surface to sag

Viable concept developed

It was during this phase that the company became aware of linear shoring and found a competent partner in thyssenkrupp Infrastrucure, with whom it developed a viable concept for securing an excavation at this depth. The construction partners made use of this concept to secure the excavation pit in Berlin-Frohnau, using what is known as deeper linear shoring.

Deeper linear shoring, in which two shoring units are coupled together, combines the advantages of the linear shoring system into a high-performance functional principle, which was the obvious choice in view of the general conditions prevailing in the sewer construction project. Unlike conventional linear shoring, the first module, which is placed in the ground, consists of doubled pairs of beams connected to each other at the upper end by a tension adapter.

In the excavation pit thus secured, the damaged pipes could be replaced and, in addition, a shaft structure renewed before the excavation pit was successively backfilled while simultaneously pulling out the shoring elements.

you might also be interested in

-

New Embankment For Logport II in Duisburg

Due to the growing demand of the logistics industry, a new logistics center was established in the Port of Duisburg - Logport II. A new embankment was built over a length of 360m.

To the post -

90 seconds for 1 meter of security

The new system is characterized by its fast installation without the need for special training. One meter of safety “grows” every 90 seconds.

To the post -

Feeder Line

Old manholes were uncovered and demolished, and in the course of laying the new pipeline, the original structures were replaced by new manholes made of precast reinforced concrete.

To the post