E+S DEEP LINEAR SHORING.

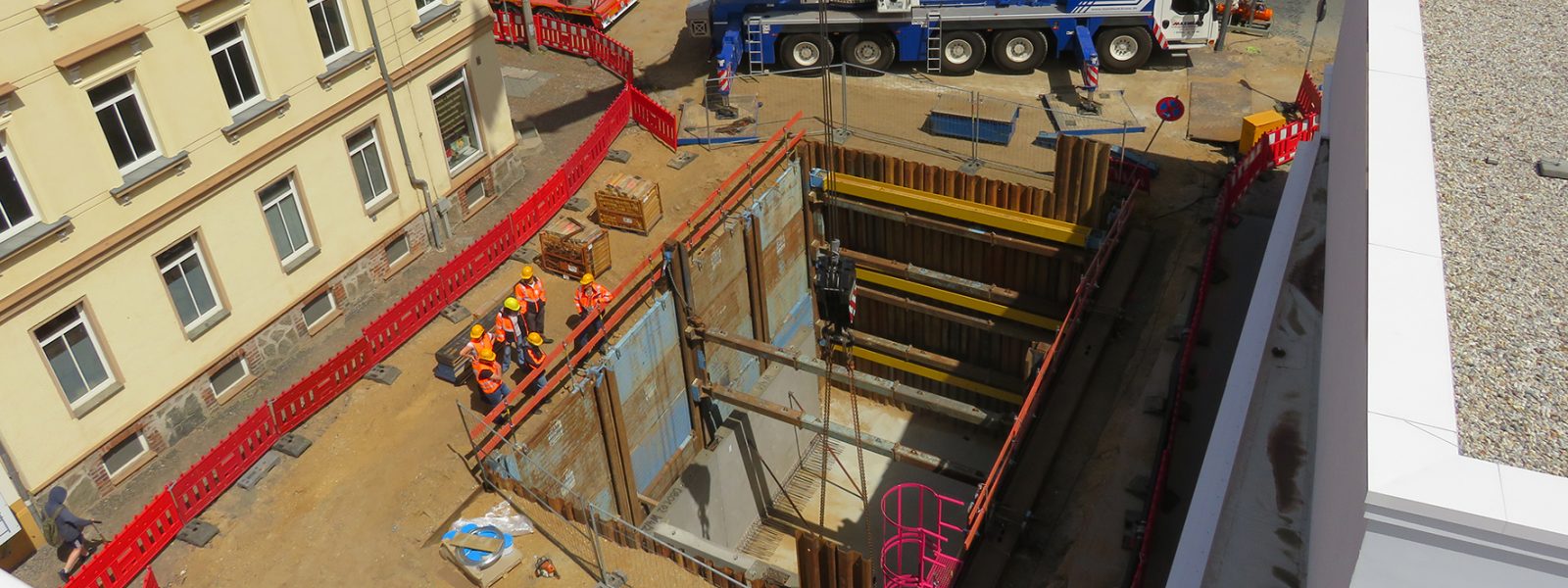

The first step involves the installation of a linear shoring module - consisting of a linear shoring soldier, panels and roller units. Then a second module is inserted into the already installed panel and, as an inner running module, is adapted to the outer module on contact. In this way, the inner shoring components take over the loads that occur when the outer module is passed through. These are absorbed again by the first module during further sinking.

The innovative process was developed specifically for applications with special depths, such as canal construction, the construction of shaft structures or press pits. By coupling two linear shoring beams, depths of well over 10 m can be realized, depending on the ground conditions - and all the construction advantages of the linear shoring system can be utilized.

SPECIFICATION

- Module length: 2.25 m - 6.50 m

- Slide rail length: variable

- Panel height: 1.32 m / 2.32 m

- Pipe clearance height: variable

- Shoring width: variable

ADVANTAGES

- Depths of well over 10 m can be realized

- With "sticky" soils even between 7 and 10 m economical

reference projects