E+S DOUBLE-SLIDE RAIL LINEAR SHORING.

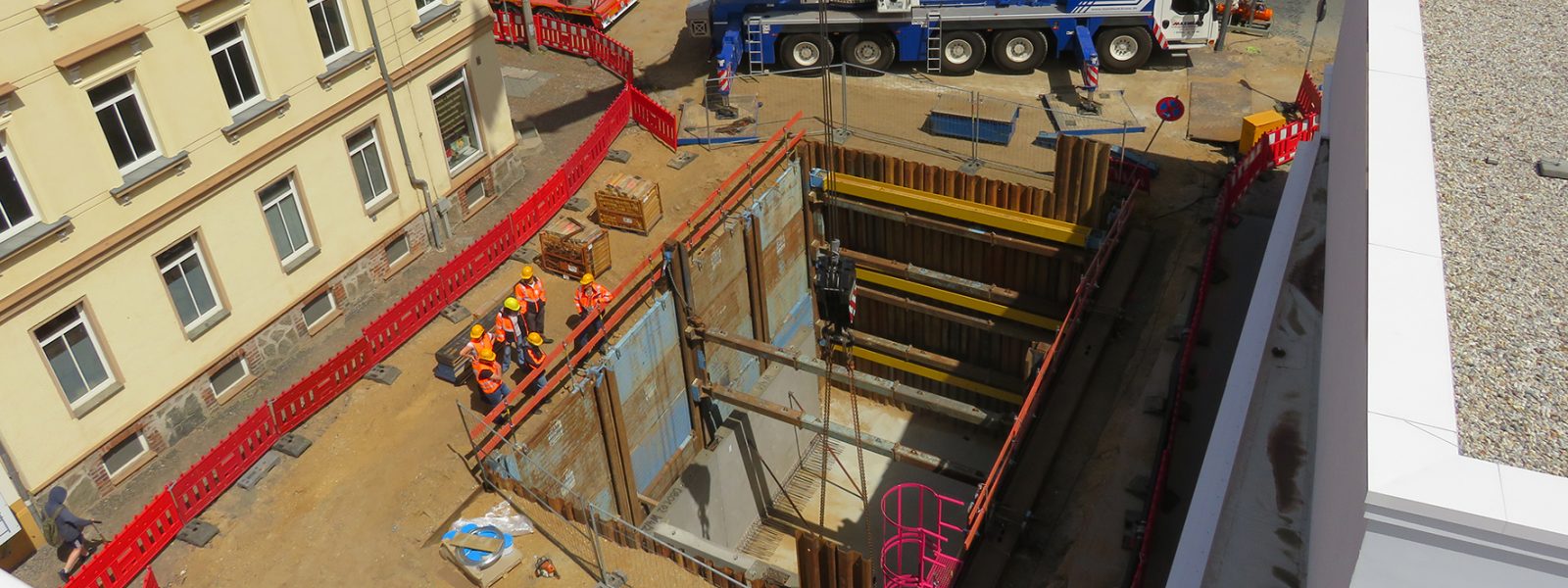

With linear shoring, which is suitable for in-situ concrete and can be used flexibly for all types of construction work, the ground outside the trench remains largely untouched, and buildings and traffic flow are hardly affected. With stepped linear shoring, these advantages can also be exploited for work at greater depths.

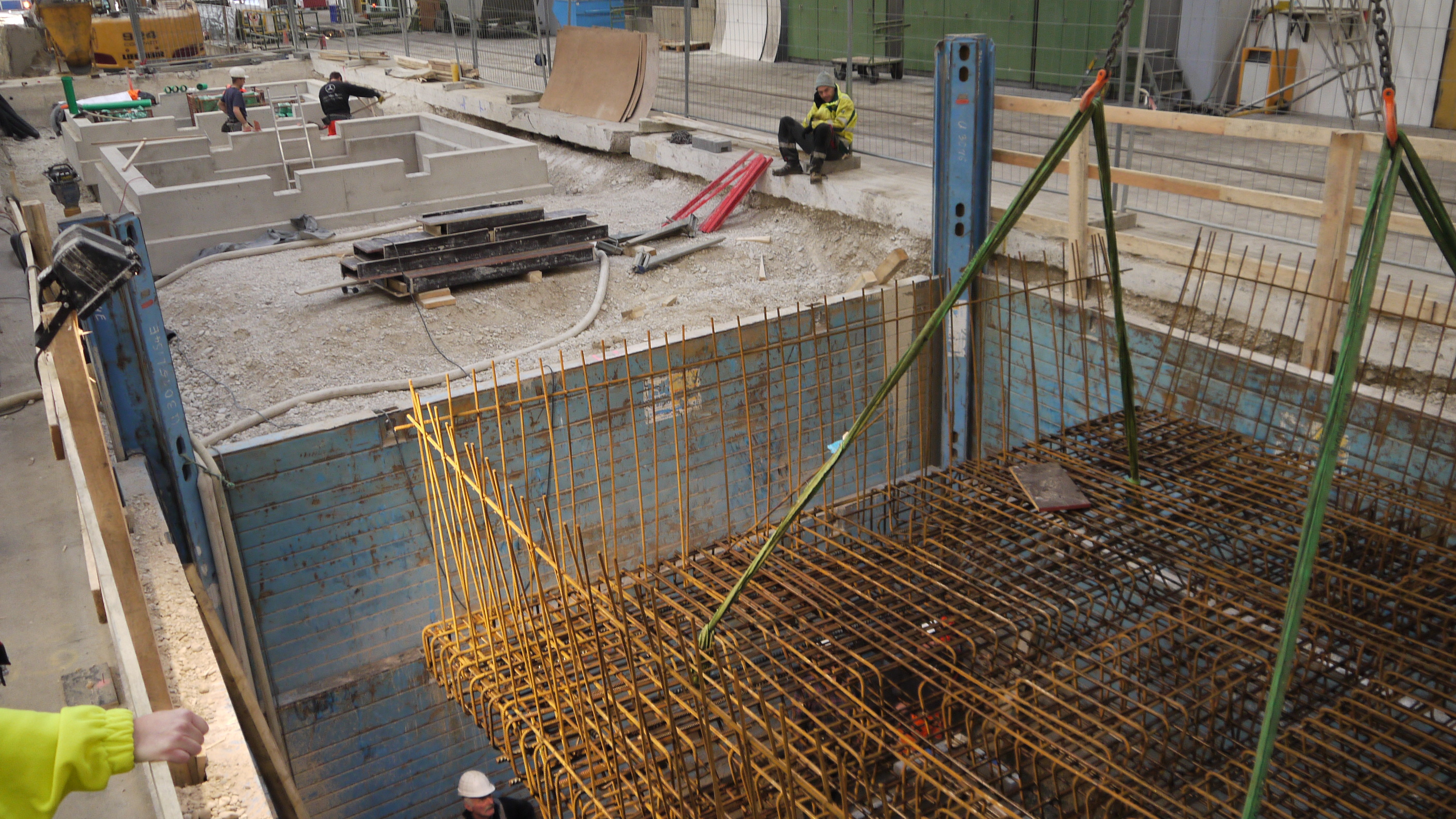

In vertically installed beams, inner and outer shoring panels are held in such a way that they can slide past each other. Since the retraction forces are much lower than with most other shoring systems, the overall cost-effectiveness of the system is increased, especially in deeper excavations. Flexurally rigid carriages, which can be adjusted in height in line with the advancing construction depth, keep the beams and shoring panels at the same distance apart at all times; the trench width remains virtually the same in every construction phase. This ensures more effective, faster, better quality and noticeably more economical work. A major advantage of the system results from the design of the girder: Only with the stepped E+S linear shoring system is it possible to swing in the shoring panels from the side.

SPECIFICATIONS

- Module length: 2.25 m - 6.50 m

- Slide rail length: 5.13 m - 9.13 m

- Plate height: 1.32 m / 2.32 m

- Pipe clearance height: variable

- Shoring width: variable

ADVANTAGES

- Shoring panels can be swung in laterally

- Economical shoring solution for deep and wide excavations

- Low-vibration and low-settlement installation

- Hardly any interference with buildings and traffic

- Low deconstruction forces

- Trench width almost the same in every construction phase

- Suitable for in-situ concrete

E+S DOUBLE-SLIDE RAIL INNER-CITY LINEAR SHORING.

In inner-city areas, trench sections with many transverse pipelines are the order of the day. The use of large-area shoring systems is out of the question in such areas. The solution for construction work at greater depths: stepped inner-city linear shoring, which is comparable in its functional principle to stepped linear shoring. Short planks are guided in a staggered manner in likewise staggered plank chamber elements. The result is two adjoining plank walls that can be pulled independently of each other.

The installation of the shoring modules and the lowering of the planks is carried out with as little vibration as possible - an important prerequisite for civil engineering work in inner-city areas.

SPECIFICATIONS

- Module length: 3.70 m

- Slide rail length: 5.13 m - 9.13 m

- Height of piling frame element: 1.00 m

- Trench sheet length (KD VI/8): variable

- Trench width: variable

ADVANTAGES

- Economical shoring for transverse lines and house connections

E+S DOUBLE-SLIDE RAIL CORNER SHORING.

Corner rail shoring is a special shoring solution that is suitable, among other things, for work on shaft structures. As a rule, the system consists of four slide rail panels and four corner rail girders. Special bracing systems are not required. All forces are absorbed by the shoring panels. By using different panel lengths in pairs, right-angled excavations of different sizes can be realized.

SPECIFICATIONS

- Module length: 2.25 m - 6.50 m

- Slide rail length: 5.13 m / 6.13 m

- slab height: 1.32 m / 2.32 m

- Shoring width: 2,13 m - 6,38 m

ADVANTAGES

- Economical shoring solution, e.g. for manholes with greater depths

- Right-angled excavations of various sizes can be realizes

reference projects

Trench Shoring - Linear Shoring

NEUBAU SAMMLER - LINEAR SHORING ENSURES LARGE AND SAFE WORKING SPACE

Read more